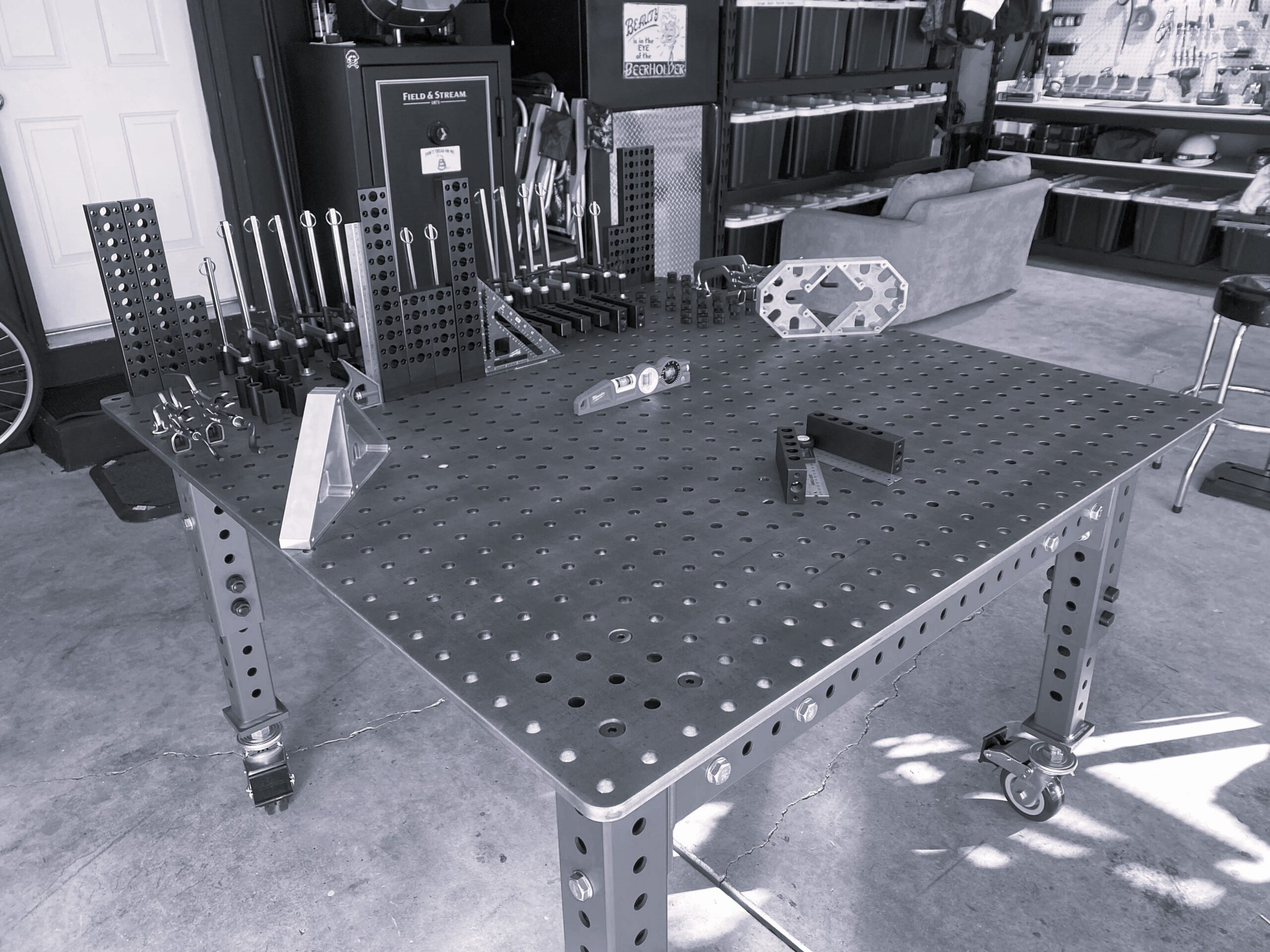

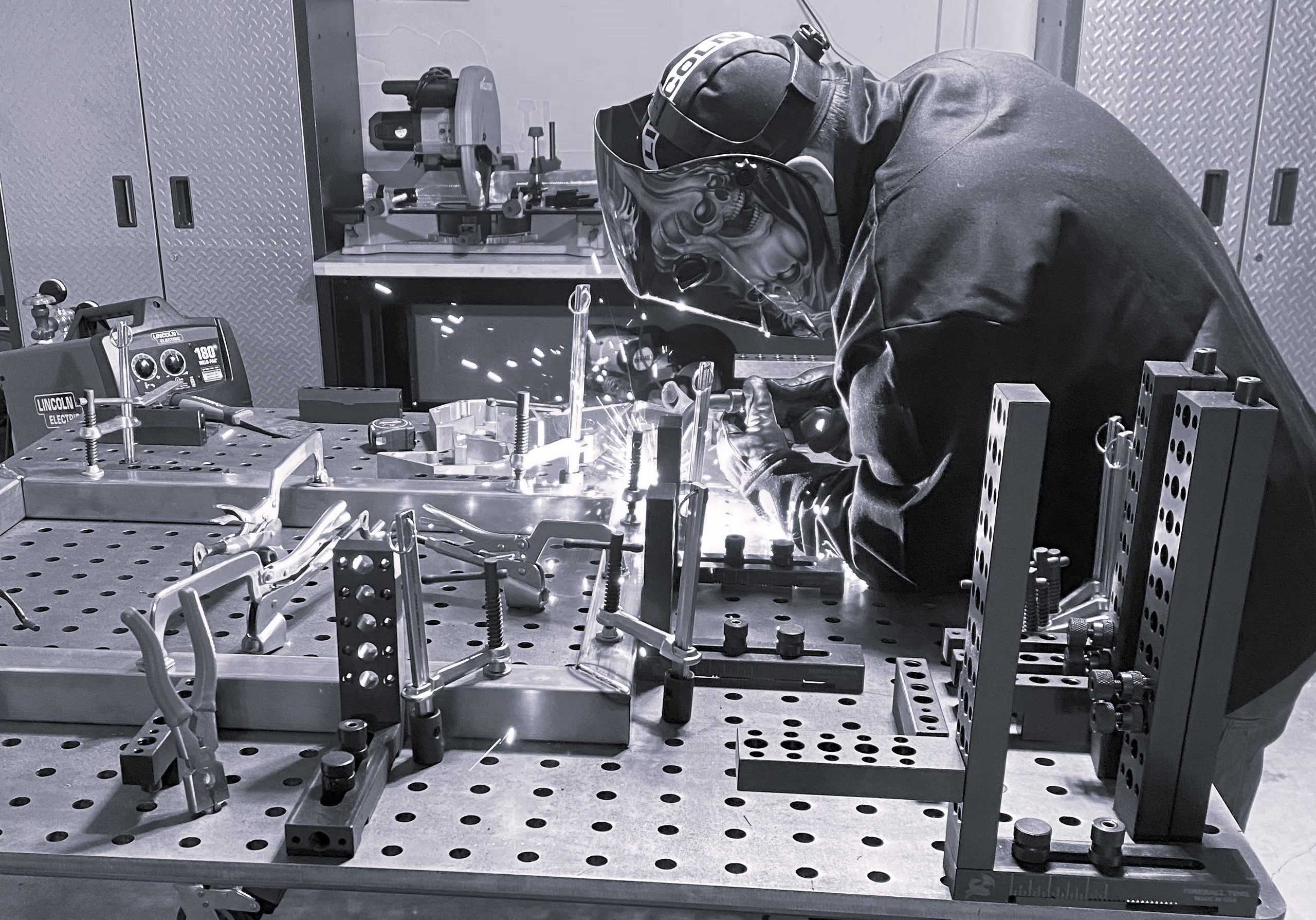

Fixture Table in Welding and Fabrication

In the world of welding and fabrication, precision and efficiency are paramount. One tool that stands out for its ability to enhance both is the fixture table. A fixture table, often the cornerstone of a well-organized welding shop, provides a multitude of benefits that can significantly improve the quality and speed of production.

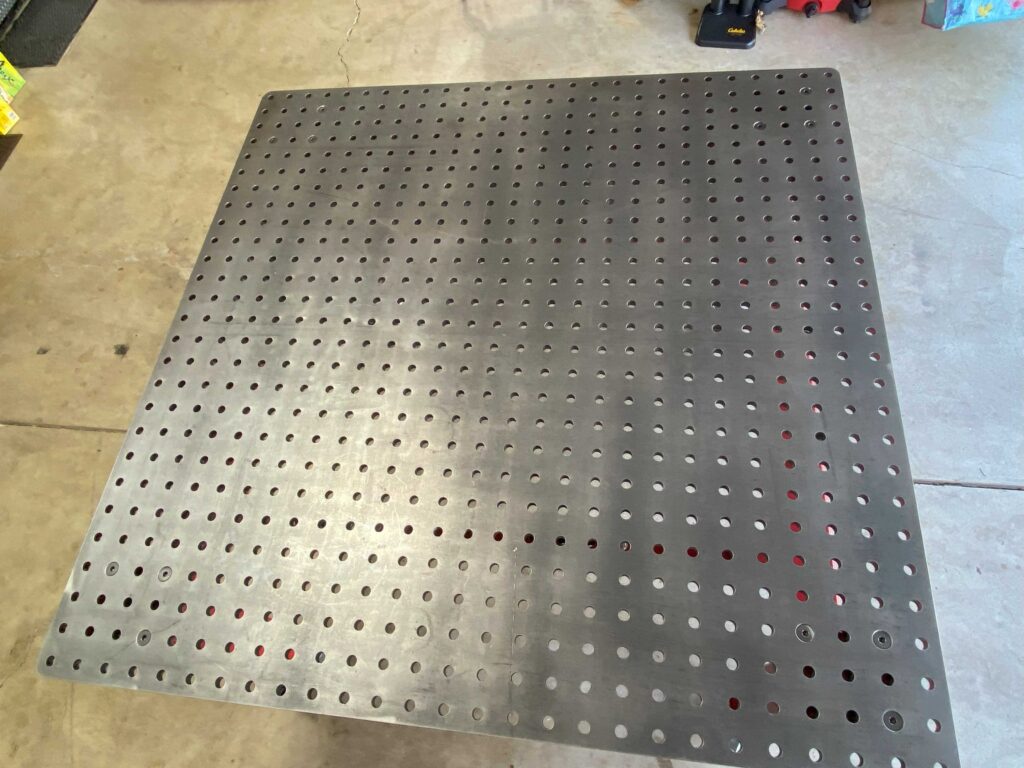

Stability and Precision

A fixture table offers a stable and flat work surface that is essential for precise welds. It minimizes vibrations and movement that could otherwise affect the welding process, ensuring that each weld is consistent with the last. This stability is crucial when working on projects that require a high degree of accuracy and where even a small error could lead to significant issues down the line.

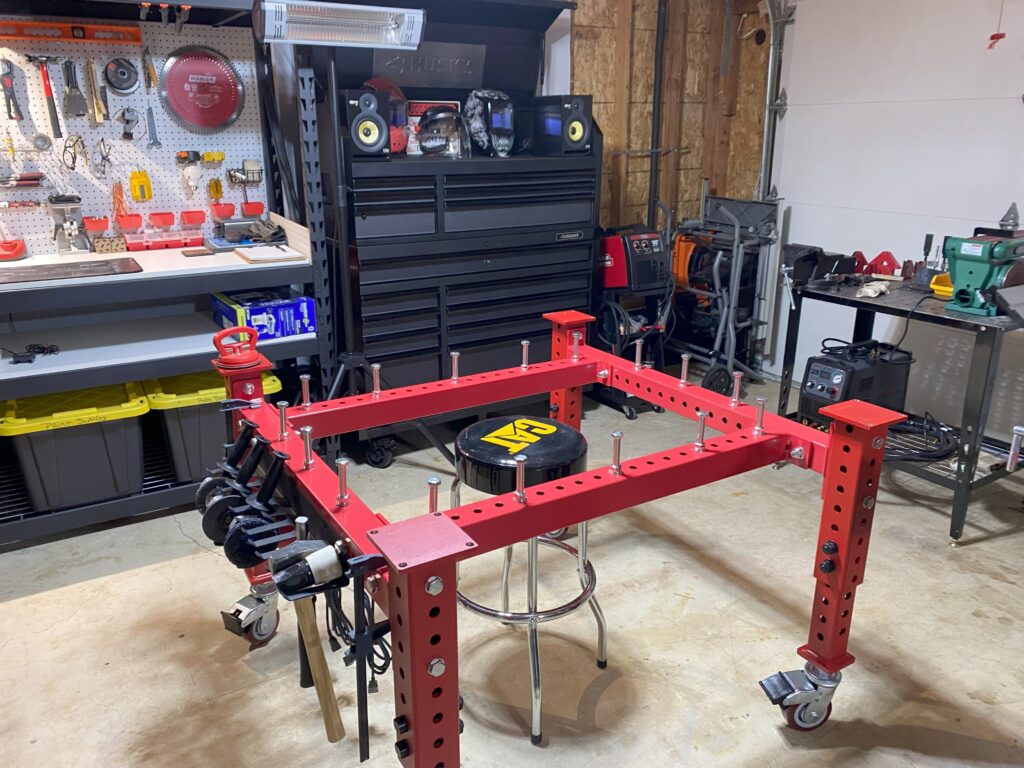

Efficiency and Streamlining

The use of a fixture table streamlines the welding process by providing a level surface that facilitates accurate measurements and alignments. This can lead to a more efficient workflow, as less time is spent on setup and adjustments. The table also allows for the quick and easy setup of jigs and fixtures, which can hold parts in the exact position needed for welding, further enhancing efficiency.

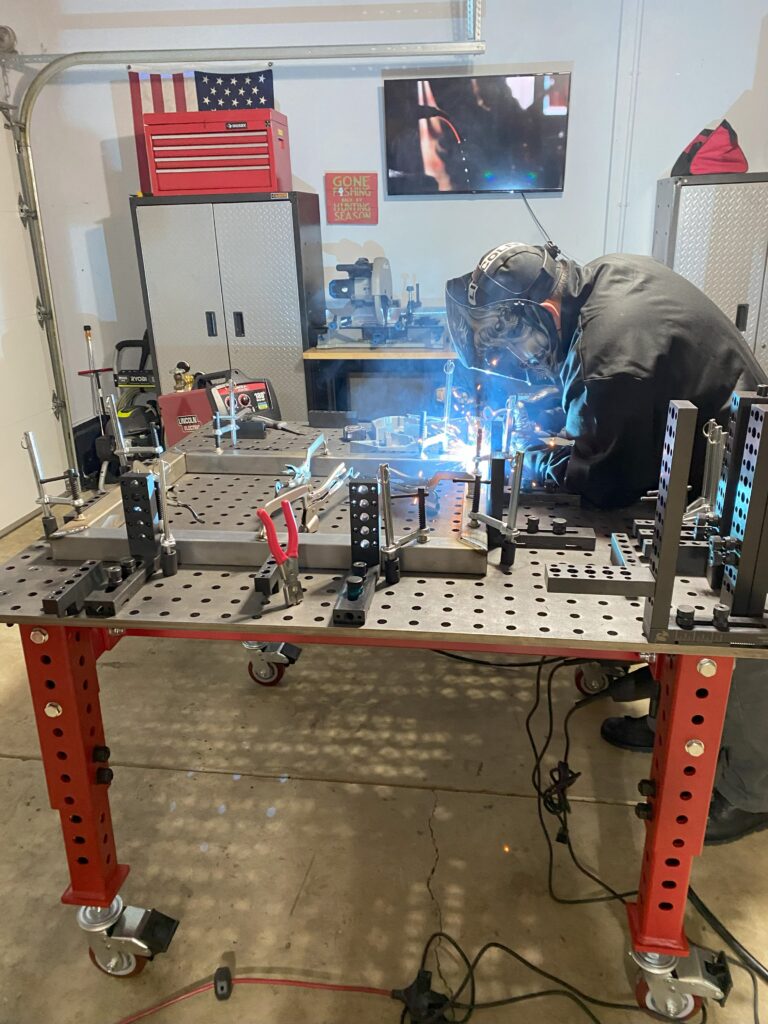

Reducing Errors and Distortions

When welding components, especially those that are long or unwieldy, there is a risk of errors and distortions. A fixture table helps to eliminate these issues by providing a solid foundation that supports the workpiece throughout the welding process. This is particularly beneficial when working with intricate or complex assemblies.

Optimizing Quality and Consistency

Quality and consistency are critical in welding and fabrication. A fixture table ensures that each weld joint is positioned correctly, leading to better overall product quality. This is especially valuable for training new welders and maintaining consistent quality across a team of less-experienced welders.

Adaptability for Various Projects

Fixture tables are versatile and can be adapted for a wide range of projects. They can accommodate different sizes and shapes of workpieces, and with the right fixtures, they can be set up for virtually any welding task. This adaptability makes them an invaluable asset in any fabrication shop.

Cost-Effectiveness

While there is an initial investment in a fixture table, the long-term benefits can lead to cost savings. By reducing errors, minimizing waste, and improving the speed of production, a fixture table can quickly pay for itself. Additionally, the improved quality of the final product can lead to higher customer satisfaction and repeat business.

Fixture tables are an essential tool in the welding and fabrication process. It provides stability, enhances precision, streamlines operations, reduces errors, and ensures quality and consistency in the final product. For any fabrication shop looking to improve its processes and output, investing in a quality fixture table is a wise decision. For more detailed insights and tips on using a fixture table, you can watch the Welding Table 101 videos listed below, also if you are interested in purchasing a fixture table that I use they are available for $2950.00 Drop me a note in the contacts page if you are interested.