Stick Welding 101: The Essential Guide

Stick welding is one of the most common and versatile welding processes, used for a wide range of applications, from construction and repair to art and hobby. Stick welding is also known by other names, such as shielded metal arc welding (SMAW), manual electrode welding, and manual metal arc welding. In this guide, we will explain the basics of stick welding, including what kind of equipment you need, how to set up your machine, how to choose the right electrodes, and how to strike an arc and make a weld.

What is Stick Welding?

Stick welding is a welding process that uses an electric current to create an arc between a metal electrode and the workpiece. The electrode is coated with a flux that melts and forms a gas shield around the arc, protecting it from the air and contaminants. The electrode also melts and fills the gap between the workpiece, creating a weld pool. The flux solidifies into a layer of slag that covers the weld pool and prevents oxidation. The slag must be removed after the weld is complete.

What are the Advantages of Stick Welding?

Stick welding has several advantages over other welding processes, such as:

- It is simple and inexpensive. You only need a power source, an electrode holder, a ground clamp, and some electrodes to start stick welding. You don’t need any gas cylinders, wire feeders, or regulators.

- It is portable and versatile. You can use stick welding in any position and on any metal that can conduct electricity. You can also weld outdoors in windy or rainy conditions, as the flux protects the arc from the elements.

- It is effective on dirty or rusty metals. The flux can penetrate through mill scale, rust, paint, or oil and create a strong bond with the base metal. You don’t need to clean the metal surface as much as with other welding processes.

What are the Disadvantages of Stick Welding?

Stick welding also has some drawbacks, such as:

- It requires more skill and practice. You have to control the arc length, travel speed, electrode angle, and electrode movement as you weld. You also have to change electrodes frequently as they burn down.

- It produces more spatter and slag. The flux creates sparks and droplets of molten metal that can fly around and damage your work area or your skin. The slag also needs to be chipped off and brushed away after each weld, which adds to the cleanup time.

- It has lower productivity and efficiency. Stick welding has a lower duty cycle than other welding processes, meaning you have to stop more often to let the machine cool down or change electrodes. Stick welding also has a lower deposition rate than other welding processes, meaning you use more electrodes to fill the same amount of metal.

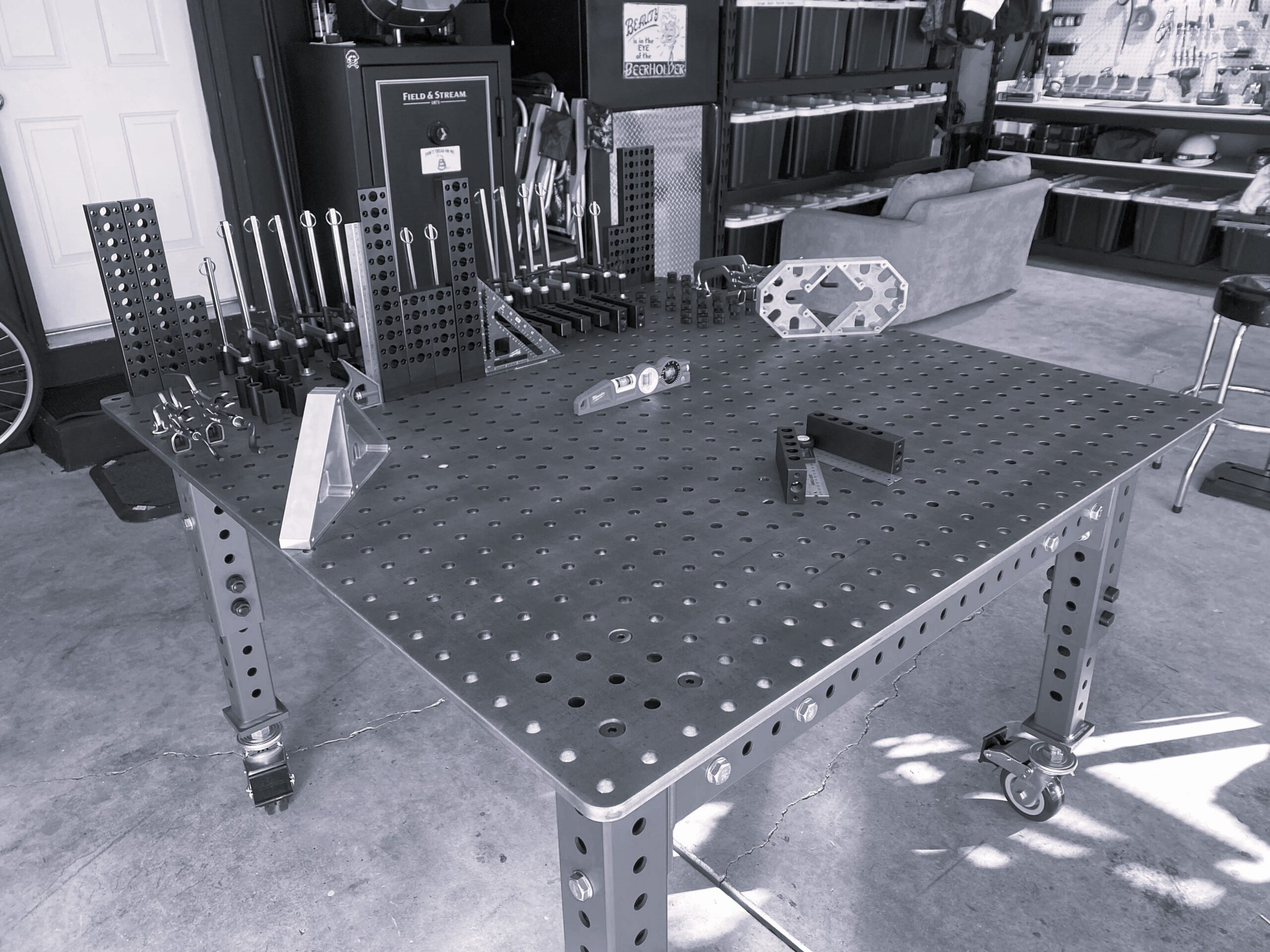

What Equipment Do You Need for Stick Welding?

To start stick welding, you need the following equipment:

- A stick welder. This is a power source that converts AC or DC electricity into a low-voltage, high-amperage current that can create an arc between the electrode and the workpiece. There are different types of stick welders available, such as transformer-based, inverter-based, engine-driven, or multiprocess machines. You should choose a stick welder that suits your budget, power supply, portability, and performance needs.

- An electrode holder. This is a device that holds the electrode securely and allows you to control its movement and angle. It also has an insulated handle that protects you from electric shock.

- A ground clamp. This is a device that connects the workpiece to the negative terminal of the power source. It ensures a complete circuit for the electric current to flow through the electrode, the arc, the workpiece, and back to the power source.

- Electrodes. These are metal rods that have a core wire and a flux coating. The core wire conducts electricity and melts into the weld pool. The flux coating melts and creates a gas shield around the arc and slag over the weld pool. There are different types of electrodes available for different metals, positions, polarities, and applications. You should choose electrodes that match your workpiece material, thickness, joint type, and desired weld quality.

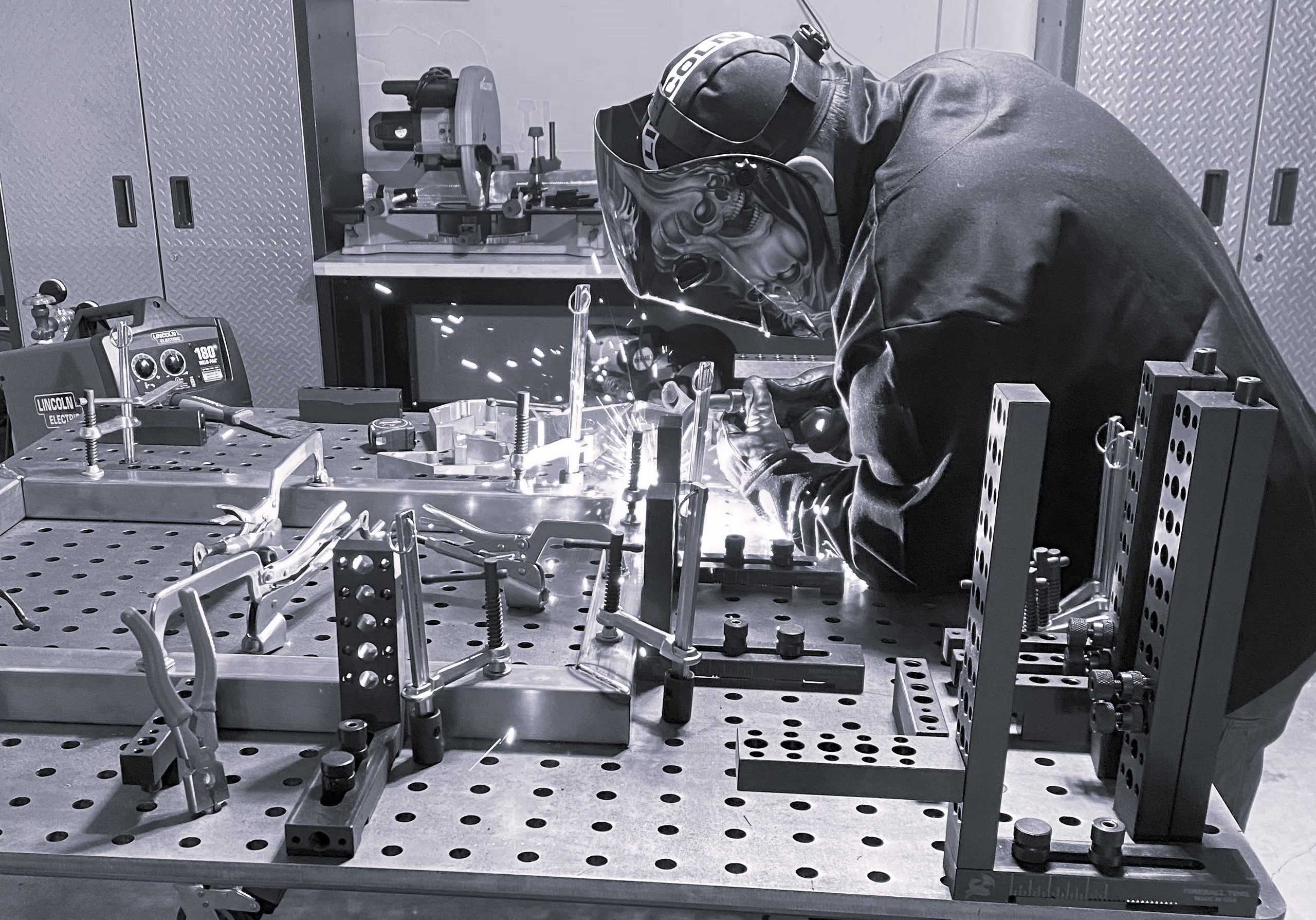

- Safety gear. This includes a welding helmet with an auto-darkening lens that protects your eyes from harmful UV rays and bright flashes; gloves that protect your hands from heat, sparks, and electric shock; a jacket that protects your body from spatter and slag; boots that protect your feet from falling objects; safety glasses that protect your eyes from flying debris; ear plugs that protect your ears from loud noises; and respirators that protect your lungs from fumes.

How to Set Up Your Machine for Stick Welding?

To set up your machine for stick welding, follow these steps:

- Connect the ground clamp to the workpiece or to a metal table where you will place your workpiece. Make sure the connection is clean and tight.

- Connect the electrode holder to the positive terminal of the power source, unless otherwise specified by the electrode type. Some electrodes require reverse polarity, meaning the electrode holder is connected to the negative terminal and the ground clamp to the positive terminal.

- Adjust the amperage according to the electrode size and polarity. The amperage determines the heat and penetration of the arc. Too low amperage will result in a weak arc that will not melt the metal properly. Too high amperage will result in a violent arc that will burn through the metal and create defects. The recommended amperage range for each electrode is usually printed on the electrode package or available online. You can also use this formula as a general guideline: Amperage = Electrode Diameter (inches) x 40. For example, if you are using a 1/8 inch electrode, you can set your amperage to 125 amps (1/8 x 40 = 125).

- Insert an electrode into the electrode holder and tighten it. Make sure the electrode is aligned with the holder and not bent or twisted.

- Turn on the power source and check if everything is working properly.

How to Choose the Right Electrodes for Stick Welding?

Electrodes are classified by a four-digit number that indicates their properties and characteristics. The first two digits indicate the tensile strength of the weld in thousands of pounds per square inch (psi). For example, an E6010 electrode has a tensile strength of 60,000 psi. The third digit indicates the position that the electrode can be used for. The positions are:

- 1: All positions (flat, horizontal, vertical, and overhead)

- 2: Flat and horizontal positions only

- 3: Flat position only

- 4: Flat, horizontal, vertical down, and overhead positions

The fourth digit indicates the type of flux coating and the current or polarity that the electrode requires. The types are:

- 0: High cellulose sodium coating; DC+ polarity

- 1: High cellulose potassium coating; AC or DC+ polarity

- 2: High titania sodium coating; AC or DC+ polarity

- 3: High titania potassium coating; AC or DC+ polarity

- 4: Iron powder titania coating; AC or DC+ polarity

- 5: Low hydrogen sodium coating; DC+ polarity

- 6: Low hydrogen potassium coating; AC or DC+ polarity

- 7: Iron powder iron oxide coating; AC or DC+ polarity

- 8: Low hydrogen iron powder coating; AC or DC+ polarity

Some electrodes may have additional letters or numbers after the four-digit number to indicate special features or applications. For example, an E7018-H4R electrode has a low hydrogen iron powder coating that can be used for all positions with AC or DC+ polarity, and has a low hydrogen content (H4) and a moisture-resistant flux (R).

The most common electrodes used for stick welding are:

- E6010: A fast-freezing electrode that produces deep penetration and a narrow weld bead. It is good for welding on dirty or rusty metals, pipe welding, and gap bridging. It requires DC+ polarity and can be used in all positions.

- E6011: Similar to E6010, but can be used with AC or DC+ polarity. It is good for welding on thin metals, sheet metal, and galvanized steel.

- E6013: A general-purpose electrode that produces moderate penetration and a smooth weld bead. It is easy to use and has low spatter and slag. It can be used with AC or DC+ polarity and in flat and horizontal positions.

- E7018: A low-hydrogen electrode that produces strong and ductile welds with low hydrogen content. It is good for welding on high-strength steels, pressure vessels, and structural steel. It requires AC or DC+ polarity and can be used in all positions.

How to Strike an Arc and Make a Weld with Stick Welding?

To strike an arc and make a weld with stick welding, follow these steps:

- Put on your safety gear and make sure your work area is clear of flammable materials.

- Hold the electrode holder in one hand and position the tip of the electrode about 1/4 inch above the workpiece where you want to start your weld.

- Strike an arc by tapping or scratching the electrode on the workpiece like a match. If you tap, lift the electrode slightly after touching the metal. If you scratch, drag the electrode along the metal until it sparks.

- Once you see an arc form between the electrode and the workpiece, move back to your starting point and maintain a short arc length, about the diameter of your electrode. If you lose your arc, repeat steps 2 and 3.

- Drag the electrode along the joint or bead at a steady speed and angle. Keep a slight angle of about.